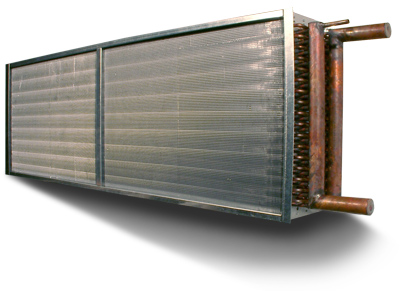

HEAT EXCHANGERS

Canada Blower has the

capability to manufacture any sized water or fluid coil necessary to

fit your application. Whether it be a small 12” x 12” coil for

replacement application to a large 12’ x 12’ custom air handler coil,

Canada Blower can build what you need. Canada Blower software allows

the design or water, glycol, oil, or any other special fluid that may

be needed. Aerofin has the ability to manufacture our coils with a

variety of tube materials, including copper, copper-nickel, carbon

steel, stainless steel, and many other non-standard materials. The

standard construction will consist of carbon steel or non-ferrous

headers with threaded pipe connections and will be supplied with vents

and drains. Other types of connections and materials, such as flanged

or Victaulic, are available.

Industrial Heat Exchange Coils

Liquid-to-Air Coils

Air-to-Air Coils

Liquid-to-Liquid Coils

Process Heat Exchangers

Steam, Water & Glycol Finned Coils

Copper, aluminum, steel, stainless steel, nickel coil construction.

Heresite are other coil coatings are available.

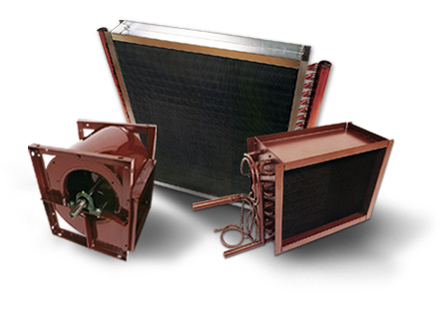

Face & Bypass Dampered Coils

Unit Heater Fans

For competitive quotations click here:

Liquid-to-Air Heat Exchangers

Air-to-Air Heat Exchangers