PROPELLER FANS

Panel fans are designed for general ventilation and process cooling involving the movement of clean, ambient temperature air. Typical Canada Blower fan applications include air filter units, casting cooling, cold room circulation, condensation control, electrical panel & transformer cooling, elimination of heat stratification, greenhouse ventilation, non-corrosive fume exhaust, parking garages, and washed parts drying.

Wall Fans

Exhaust and Supply Fans

Belt and Direct Drive

Sizes to 84" DIA

CFMs to 100,000

Pressures to 1" WG

Axial Roof Ventilators

Exhaust and Supply Ventilators

Belt and Direct Drive

Sizes to 84" DIA

CFMs to 140,000

Pressures to 14" WG

Centrifugal Roof Ventilators

CFMs to 35,000

Pressures to 2" WG

Centrifugal Wall Ventilators

CFMs to 20,000

Pressures to 3" WG

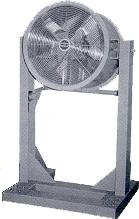

Circulating Fans

Pedestal, bracket & mobile fan types.

Sizes to 36" DIA

Multi-speed and oscillating ventilators.

- FRP and PVC plastic ventilator construction available

- High-temperature and fire resistant fan construction available

Available Fan Accesories

- backdraft and motorized air dampers

- shutters

- louvers

- cabinets

- wall sleeves

- roof curbs

- spark-resistant and explosion-proof fan construction

- safety guards

- speed controllers and safety disconnects

- emergency ventilation control centers

- filtered supply fan units

- manhole ventilators

- gasoline driven fans.